Reciprocating Pumps

Sefco piston pumps are the ideal solution for pumping cryogenic fluids under high pressure.

Specially developed for cryogenic media such as oxygen, nitrogen and argon, they employ compact design and flexible skid integration. This results in space-saving system solutions for fast and safe cylinder filling as well as the filling of stationary storage tanks. Their robust construction utilizing modern and unique pre-compressor technology ensure low-maintenance, reliable operation and consistently high performance.

Do you have any questions?

Please do not hesitate to contact us. We look forward to hearing from you — by phone or email.

Technology

Precisely matched components, robust materials and a sophisticated operating principle form the basis of Sefco piston pump technology. The combination of a pre-compression stage, controlled pressure generation and efficient media flow enables consistent delivery, even at low inlet pressures and highly dynamic operating cycles.

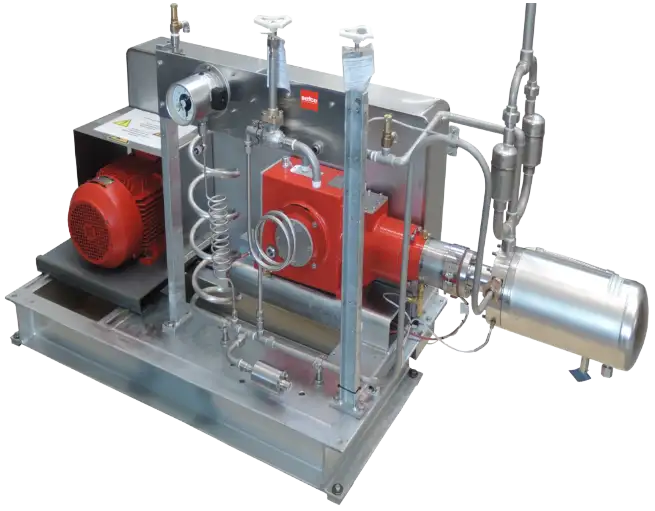

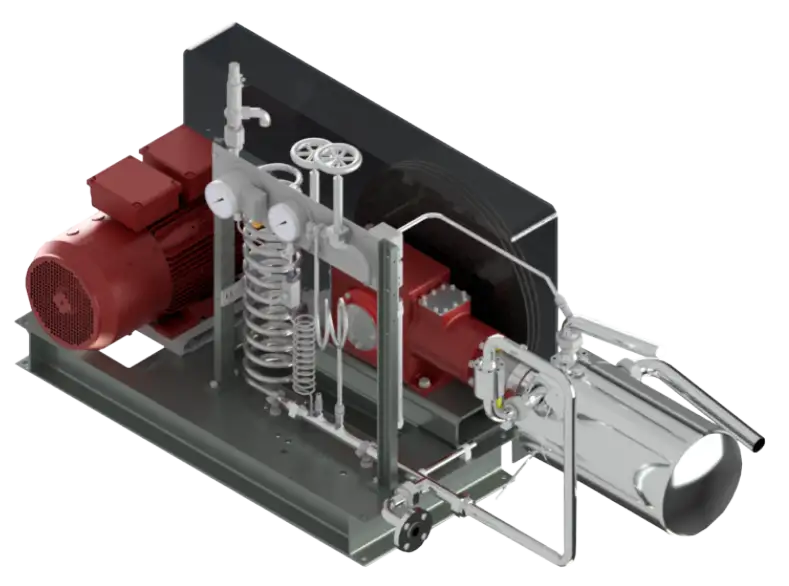

The model shown is an example of all SEFCO reciprocating pumps and may vary depending on the type and equipment.

Drive

Sefco piston pumps are driven by an electric motor as standard, the power rating of which is individually adapted to the respective operating conditions. Not only the delivery rate, but also the expected pressures and thermal behavior in the system are taken into account.

Features

- Electromotor with customized design

- Direct or indirect drive possible

- Suitable for continuous operation with variable loads

- Adaptable to different supply voltages

- Low maintenance thanks to robust construction

Pulsation damper

Since piston pumps have an oscillating delivery characteristic, pulsations occur in the pressure line. These can lead to vibrations and uneven flow. To minimize these effects, a gas volume is used to help even-out the delivery pressure pulsations. This effectively smooths out the pressure surges.

Features

- Reduction of pressure pulsations in the delivery line

- Extension of the service life of downstream components

- Works purely passively via gas cushions

- Directly integrated into the pump system.

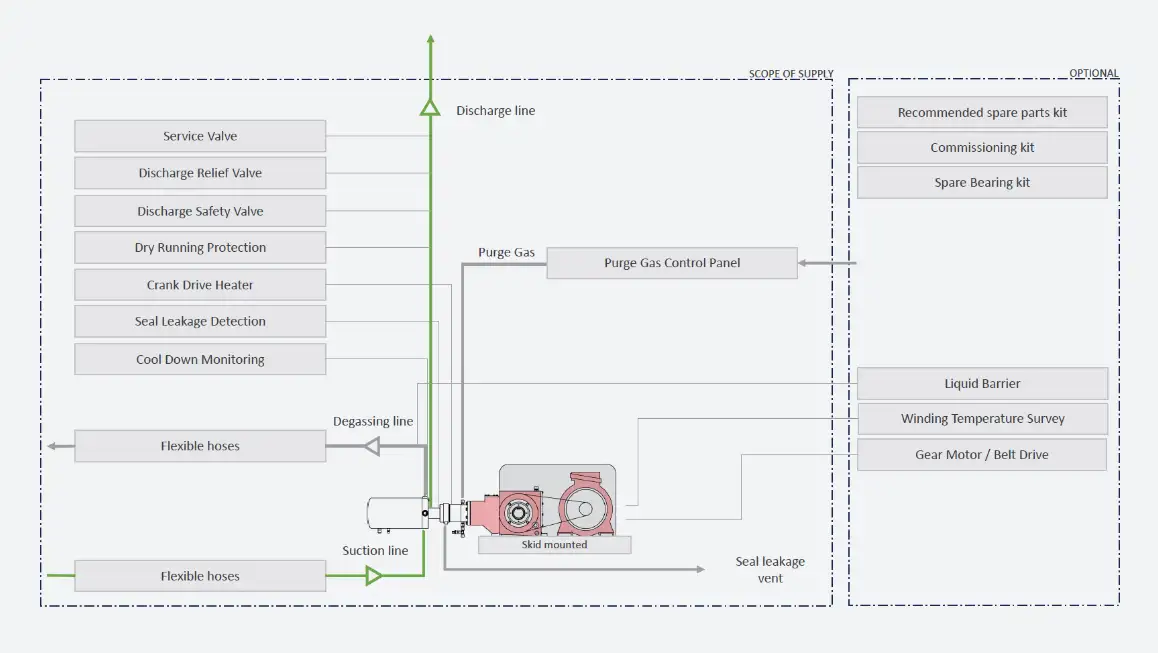

System unit

(pre-assembled base plate, aka “Skid”)

All the pump’s central components, from the motor to the cold end, are pre-assembled on a robust steel frame. This system unit (‘skid’) not only simplifies installation but also ensures that all components are optimally aligned and work together seamlessly, both mechanically and thermally.

Features

- Drive unit and power transmission

- T4 crank gear

- Cold pump end with or without vacuum jacket

- Pulsation damper and degassing connections

- Integrated safety valves and process connections.

Power transmission

Power is transmitted from the electric motor to the crank mechanism either via a belt drive or a gear drive. The choice depends on the required torque, the desired transmission ratio, and the thermal requirements. While belt drives require less maintenance, gear drives can transmit higher loads in a compact design.

Belt drive

- Simple design and maintenance

- Good thermal decoupling between motor and gearbox

- Limited transmissible torque

Gear drive

- High torque transmission possible

- Individual transmission ratios can be achieved

- Longer maintenance intervals and more complex assembly

Crank gear T4

The T4 crank gear forms the mechanical center of the pump. It converts the rotary motion of the drive into a linear piston movement. Specially designed eccentrics, robust bearings, and continuous oil lubrication are used to ensure a long service life even with high piston forces.

Features

- Oil-lubricated bearings and moving parts

- Integrated oil pump for reliable lubrication

- Designed for piston forces up to 55 kN (12,365 lbf)

- Eccentrics available for 50 mm (1.97 inch), or 60 mm (2.36 inch) stroke

- Thermally expandable cylinder bushing

Cold pump end

It is specially designed for pumping cryogenic liquefied gases. Our unique integrated pre-compression stage reduces dead volume, resulting in better filling of the piston chamber. Optionally, the cold end can be vacuum insulated to minimize heat loss and unwanted evaporation.

Features

- Unique Pre-compression stage for high fill levels

- Reduced dead volume for effective pumping and smoother running operation

- Low NPSH value due to stable suction conditions

- Optional vacuum insulation for minimal heat input.

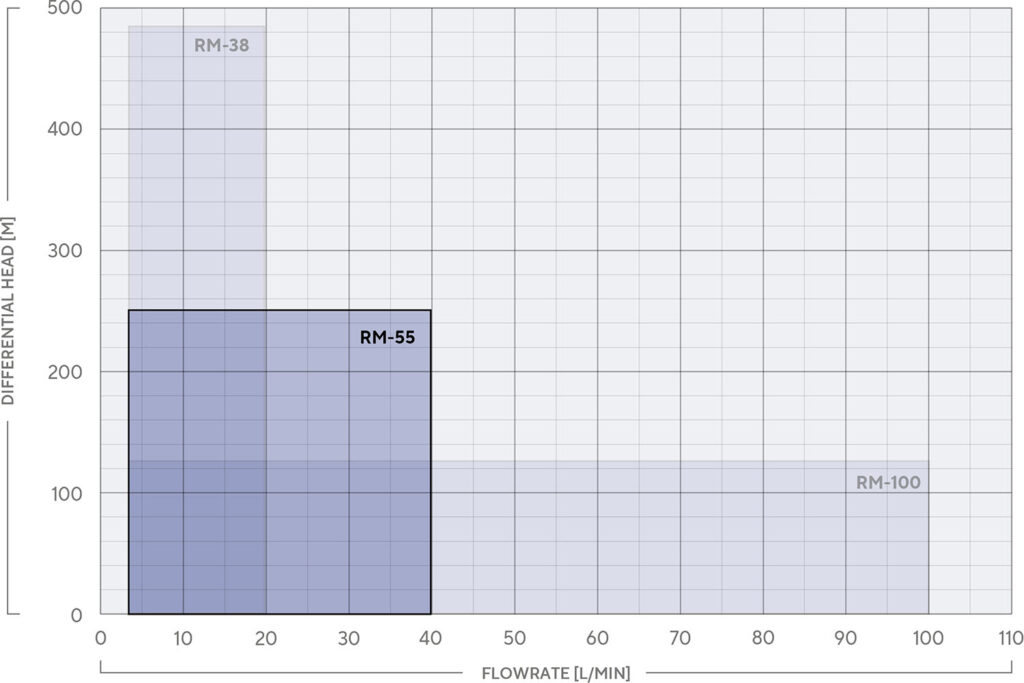

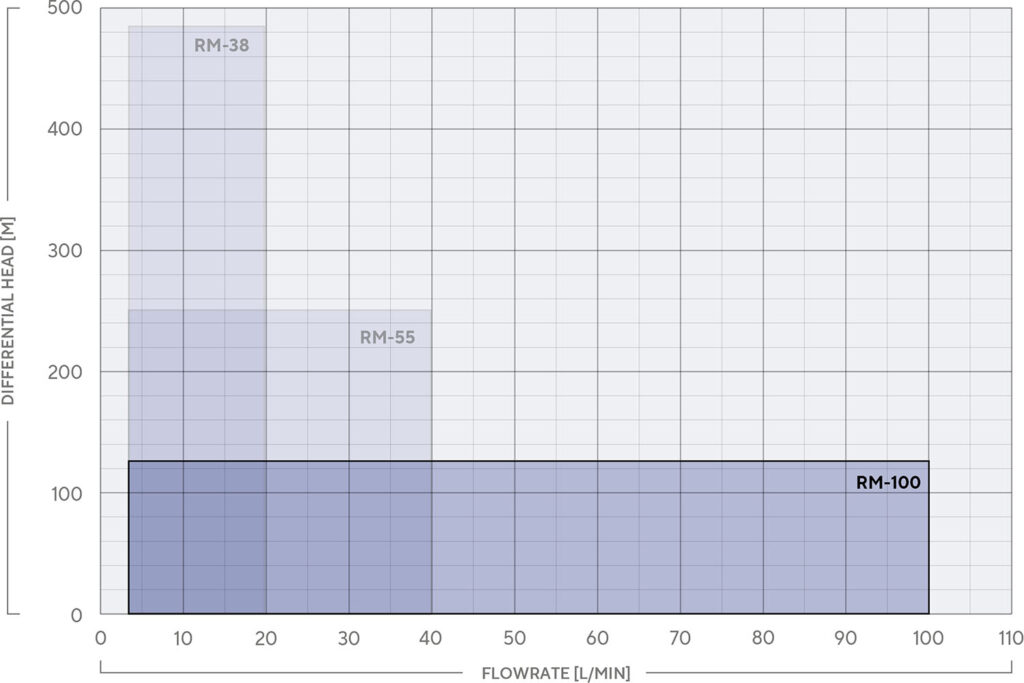

Performance and Features

«Testimonial ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam vlorema.»

Name Nachname, Funktion