Quality & Safety

Quality assurance

Our quality assurance programme incorporates state-of-the-art testing procedures, full traceability and ongoing process optimisation. This enables us to guarantee that every cryogenic pump meets the highest industry standards and can be operated reliably and safely in the long term.

Komponenten unserer Qualitätssicherung

Certification

Sefco AG is ISO 9001 certified and thus relies on a comprehensive quality management system that ensures the highest standards in all areas of the company and emphasizes continuous improvement, reliability, and high product and service quality.

Reliable suppliers

High-quality components and maximum delivery reliability begin with selecting the right partners. Critical components are sourced exclusively from qualified European suppliers who undergo regular quality audits. Close cooperation, high standards, and seamless batch tracking ensure transparency, reliability, and consistently high product quality.

Test equipment management

Effective management of test equipment ensures that all measuring and testing devices used meet the rigorous standards of our quality processes. Through regular calibration and thorough documentation, we guarantee precise measurement results and consistently high process reliability.

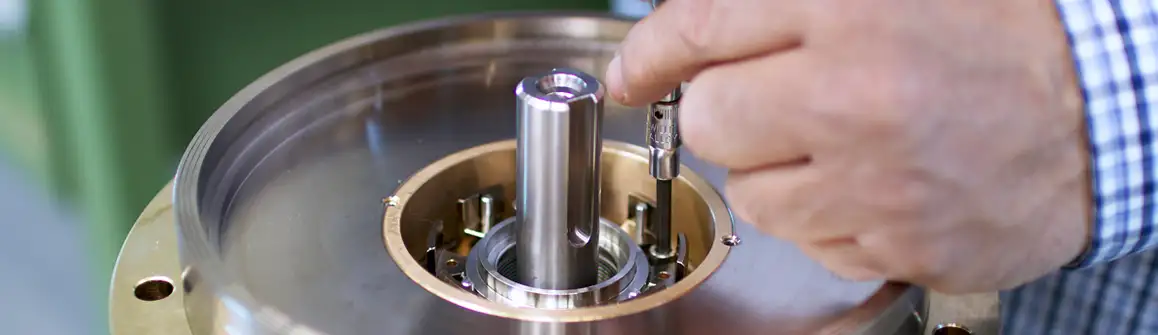

Comprehensive quality assurance

Top quality is not a matter of chance, but the result of clearly defined processes, strict testing procedures, and careful assembly. Incoming components are subject to comprehensive quality control, including non-destructive testing methods, to ensure maximum product safety even before assembly. Rotating components are precisely balanced at high speeds before installation to guarantee efficiency, durability, and smooth operation. The subsequent assembly is carried out by trained specialists in specially equipped clean rooms, under strictly controlled conditions and according to standardized procedures.

Tested product quality

Before delivery, each pump is tested in our test facility using liquid nitrogen. Key performance characteristics such as flow rate, pressure, and energy consumption are continuously monitored during this process. All models are designed and approved for use with liquid oxygen as standard, regardless of their subsequent application.

Safety protection

Through consistent safety standards, regular training, and continuous optimization, Sefco ensures safe operation and a protected working environment that always complies with the latest regulations.

Regular training and audits

Sefco employees receive regular training to ensure they are always familiar with the latest safety technology. At the same time, Sefco is continuously reviewing and optimising its production facilities and processes to maintain the highest safety standards at all times.

Certification

At Sefco AG, quality, environmental protection and safety lie at the heart of everything we do.

Our cryopumps and services are the result of our consistent pursuit of excellence and reliability. We understand that the quality of our products plays a significant role in our customers’ success. You can rely on that, as evidenced by our comprehensive certifications and commitment to responsibility.

Download