Centrifugal Pumps

Whether unloading tank trucks, transferring to storage tanks, or transferring to industrial processes, Sefco centrifugal pumps move cryogenic liquefied gases safely, efficiently, and reliably.

Developed to meet the highest demands, they cover a wide range of applications with their strong performance, compact design, and long service life. Our portfolio includes both standardized solutions for mobile applications and individually designed pumps for complex stationary requirements. It ranges from robust tanker pumps and powerful transfer pumps to precisely tuned process pumps for continuous operation. Every product stands for the highest quality, reliable function, and optimal integration into your plant.

Do you have any questions?

Please do not hesitate to contact us. We look forward to hearing from you — by phone or email.

Technology

A key feature of Sefco centrifugal pumps is their predominant modular design. Components such as impellers, diffusers, inducers, seals, drives, and bearings can be flexibly mixed and matched from several selections, and thereby are adapted to the medium, application, and operating profile. This results in performance-optimized solutions that can be individually configured without compromising on standardization or ease of maintenance.

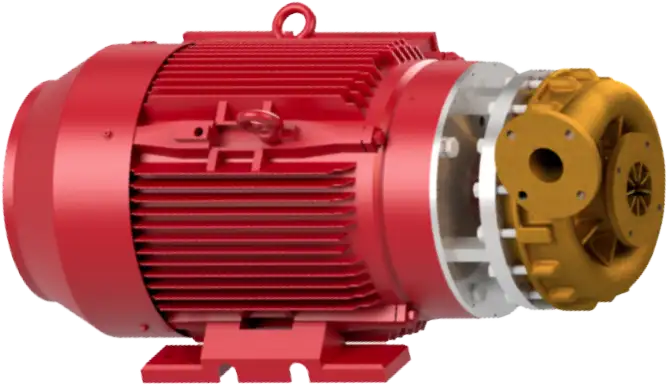

Drive

Our drive units are individually tailored to meet the specific requirements of our customers, ensuring optimum performance and maximum efficiency. Whether electric or hydraulic, each motor is carefully selected and adapted to meet the operating conditions. To enable flexible speed control, the motors can be operated either directly at mains frequency or via a frequency converter. In addition, a modular gearbox is available to enable various transmission ratios and ensure precise speed transmission.

Depending on the application area, the drive can be equipped with accessories such as bearing heating, winding protection or temperature monitoring. To minimise vibrations and oscillations, the cold end of the pump is connected directly to the motor shaft. For multistage pumps, a coupling can be integrated as an optional extra. The robust stainless steel shaft ensures high stability, reduces mechanical wear and guarantees a long service life for the pumps.

Features

- Wide range of hydraulic and electric drives for maximum efficiency, customised for optimal performance.

- Modular gear options with different gear ratios for optimal speed transmission

- Reduced oscillations and vibrations thanks to the cold pump end being mounted directly onto the motor shaft.

- Longer pump service life thanks to the robust stainless steel shaft’s high stability and low wear.

- Optional accessories such as bearing heating, winding protection and temperature monitoring ensure safe operation.

- Compatible with frequency converters for flexible speed control.

Seal

Mechanical seal (GRD)

The mechanical seal (GRD) is specially designed for applications with intermittent operating cycles. It consists of a robust stainless steel bellows, a ceramic sliding ring, and a PTFE composite counterpart, which together ensure a secure and durable seal for the pump shaft. Thanks to the high-quality materials, this seal offers reliable protection against leaks and reduces maintenance requirements, ideal for cryogenic processes with varying running times.

Features

- Corrosion-resistant and durable

- Excellent sealing performance under changing operating conditions

- Optimised for intermittent operation

- Requires little maintenance thanks to its robust materials

Non-contact mechanical seal (GRS):

The Gas Riding Seal (GRS) is an innovative solution for pumps with both continuous and discontinuous operation. At speeds of around 1,500 rpm and above, a gas cushion forms between the sealing surfaces, significantly reducing wear. This low-maintenance seal does not require any customer-supplied barrier gas nor gas-control panel, and provides reliable sealing over medium to long operating periods, making it ideal for trailer, transfer and reserve pumps.

Features

- Suitable for intermittent and continuous applications with medium to high operating times

- No customer-supplied barrier gas required

- Low wear due to gas cushion formation

- Low maintenance and long service life

Labyrinth gas seal

The labyrinth gas seal is ideal for applications with continuous operation and high throughput requirements. Nitrogen is usually used as the sealing medium, which travels through the complex, special long-length labyrinth structure. The reduction in pressure and flow velocity effectively prevents the medium from escaping. This design enables wear-free operation and ensures maximum reliability even under demanding conditions.

Features

- Effective sealing even with high pressure differences

- Wear-free mechanism thanks to labyrinth design

- Suitable for continuous operation

- High operational reliability and long service life

Modular Design

Pump impeller

The impellers of Sefco centrifugal pumps are made of an extremely durable bronze-copper alloy and are manufactured using precise machining techniques, including dynamic balancing. Their innovative and unique “exit-diffuser” design optimises pressure equalisation, reduces the load on the thrust bearings and enables stable, low-maintenance operation, even under changing process conditions. A range of impeller sizes and exit-diffuser geometries, are available to allow precise adaptation to different flow rates and pressure ranges.

Features

- Robust, high-quality bronze-copper alloy for a long service life

- Optimized pressure compensation to reduce axial load

- Static and dynamic balancing for smooth running

- Various sizes for application-specific design

- Stable operation even under changing delivery conditions

Diffusor

The high-pressure and multistage models of Sefco centrifugal pumps are equipped with specially developed exit-diffusers. These reduce the flow velocity at the impeller outlet and convert the dynamic pressure into static pressure. This achieves effective energy transfer and even pressure distribution around the volute casing. As a result, radial forces that can typically lead to shaft deformation or bearing wear are minimized. Various diffuser sizes and geometries are available for all pump types, enabling quiet and stable operation across the entire performance range.

Features

- Optimal pressure conversion for increased efficiency.

- Reduced bearing and shaft load thanks to even pressure distribution

- Stable and quiet operation with variable flow

- Various diffuser sizes available for all pump types

- Particularly suitable for high-pressure and multistage applications.

Inducer

To improve suction performance, Sefco centrifugal pumps can be equipped with an inducer and blade ring. The inducer lowers the required NPSH value and thus reduces the risk of cavitation, even under critical suction conditions. Unlike most other pump suppliers, Sefco can provide a number of different inducer designs, each version provides the lowered NPSH characteristic at a different portion of the pump’s performance curve. The vane ring at the pump inlet also reduces flow turbulence, thereby increasing running smoothness and efficiency. The result is a longer pump service life and greater operational reliability. Precisely fitting inducer variants are available for all pump sizes and can be specifically tailored to the respective application.

Features

- More stable suction behavior thanks to inducer technology

- Lower NPSH value – ideal for applications with low inlet pressure

- Reduced risk of cavitation

- Guide vanes for flow stabilization and increased efficiency

- Longer service life and increased running smoothness

Types of centrifugal pumps

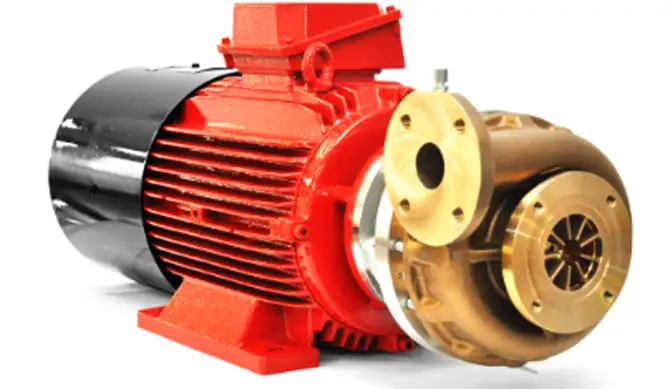

Single-stage mobile

Compact, reliable, and ready for immediate use: our mobile single-stage centrifugal pumps are specially designed for applications such as filling and emptying tank trucks. They feature ease of use, robust construction, and rapid availability. Ideal for flexible use on site, wherever performance meets mobility.

Single-stage stationary

Efficient in design, powerful in performance: Sefco’s single-stage stationary centrifugal pumps are the first choice for the reliable transfer of cryogenic liquids in storage tanks or process systems. With a clear focus on operational safety and durability, they offer an economical solution for numerous stationary applications.

Multi-stage stationary

Maximum delivery head with compact design: Our multi-stage stationary centrifugal pumps have been developed for the most demanding requirements in continuous industrial processes. They deliver stable performance over long operating times and can be precisely designed for customer-specific pressure conditions – perfect for demanding cryogenic applications.